Analytical and Crystallization Software

The best weapon for analyzing crystal materials

Materials Studio's analytical and crystallization software helps investigate, predict, and modify crystal structure and crystal growth. You can simulate particle morphology, predict crystal structure and understand polymorphism, study surface interactions, and design growth mediating additives. Applications include drug candidates, pigments, scale inhibition and explosives.

The Modules of Analytical and Crystallization Software are shown as follows:

Morphology

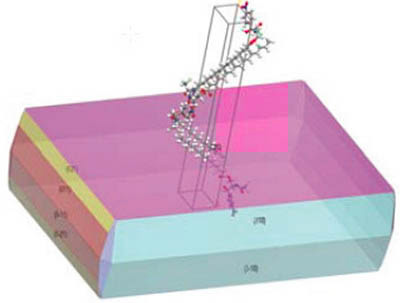

The Morphology module predicts the external morphology of crystalline materials from the internal crystal structure. Crystal attributes such as interplanar angles, aspect ratio, and surface areas can also be calculated.

The bulk shape of crystals is critically important to many industrial processes and plays a role in handling, formulation, packaging, and product performance. The relationship between crystal morphology and the internal arrangement of atoms in the crystal is therefore of great interest. Rationalization of this relationship allows the prediction of crystal shape and analysis of surface chemistry for the development of additives and the control of solvent and impurity effects.

Morphology provides a fast pathway for the application of computational techniques to solve real crystallization problems.

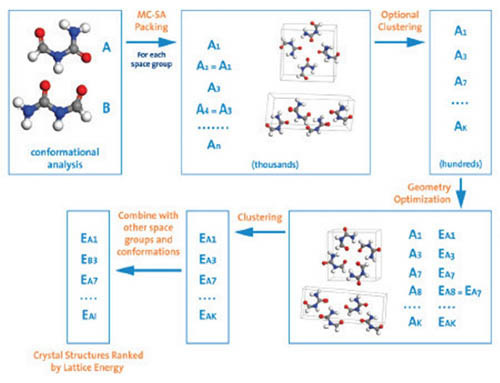

Polymorph Predictor

BIOVIA Materials Studio Polymorph Predictor allows you to predict potential polymorphs of a given compound directly from the molecular structure. Polymorphism is the ability for a compound to crystallize in more than one chemically identical but crystallographically distinct form. Crystalline materials are prevalent in many industries, including pharmaceuticals, agrochemicals, pigments, pharmaceuticals, agrochemicals, pigments, dyes, explosives, and specialty chemicals Polymorphs may differ in key properties such as shelf-life, bioavailability, solubility, morphology, vapor pressure, density, color, and shock sensitivity. It is therefore important to know how many polymorphs are possible as well as how their properties might differ when working in the solid state.

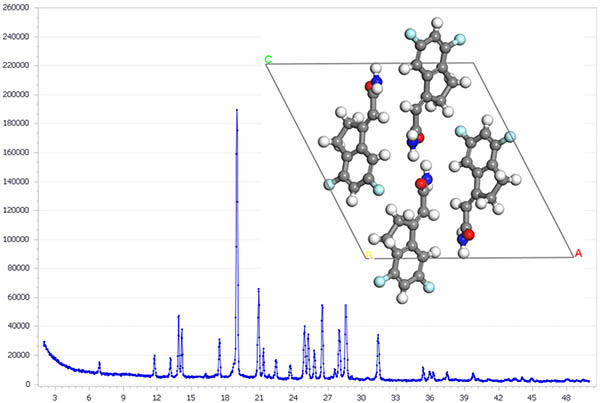

Reflex Plus

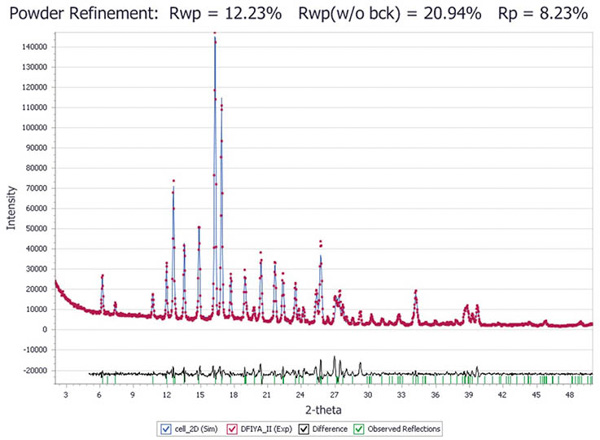

Reflex Plus is an advanced version of Reflex, adding the extensively validated Powder Solve technology to the standard Reflex functionality. Reflex Plus offers a complete package for the determination of crystal structures from high quality powder diffraction data.

The Powder Solve approach:

- The Powder Indexing tools determine the cell parameters and crystal system by indexing the experimental powder diffraction pattern.

- The modified Pawley procedure available in the Powder Refinement module refines the cell parameters, peak shape, and background parameters, and is also helpful for narrowing down the list of possible space groups.

- The Powder Solve method performs a search of possible arrangements and conformations of the molecular fragments in the unit cell. It finds a structure whose simulated powder pattern matches the experimental one as closely as possible.

A final refinement of the proposed solution is performed with the rigid-body Rietveld refinement functionality available in Reflex.

Reflex QPA

Powder Quantitative Phase Analysis allows the determination of the relative amounts of different phases in a mixture from a powder diffraction pattern of the mixture. The pure component phases that comprise the mixture may be represented by single crystal structures (the diffraction pattern is represented as the superposition of powder diffraction patterns simulated from the crystal structures of the component phases), experimental powder diffraction patterns (both standardless QPA and the internal standard method are supported), or, using a novel approach, a mixture of both.

X-Cell

X-Cell (Neumann, 2003) is a new and novel indexing algorithm that makes use of systematic absences to facilitate the search for possible indexing solutions. It performs a complete search of unit cell space, going from cells with low numbers of calculated reflections to cells with high numbers of calculated reflections. A choice of impurity tolerance levels allows you to specify the maximum number of unindexed reflections. The search is carried out such that more likely solutions are considered first. For a given number range of reflections, a given pattern of systematic absences and a given impurity tolerance level, an exhaustive search is performed using a successive dichotomy procedure. The zero-point shift is determined as part of the indexing process. All indexing solutions are fully optimized, compared, and ranked according to a special figure of merit.